Have you heard about “150% BOM”? BOM management terminology is confusing sometimes. Ed Lopategui gave a shot to explain it in his last GrabCAD blog – 150% BOM: Buy Two, Get One Free. The following passage was my favorite:

A 150% BOM isn’t sorely in need of some fitness training or sadly overdrawn at the bank. In fact, a 150% BOM is just another name for a variant structure, or more specifically, a configurable BOM. Configurable BOMs have one or more optional components and/or modular subassemblies, which, when properly set, define a specific variation of a product. In effect, a configurable BOM is many possible BOMs loaded into just one product structure. When left unconfigured, the BOM contains more parts and subassemblies than needed, i.e. more than 100%. Hence, the term 150% BOM. So why 150% and not 110% or 117.32%? That’s just the we way we roll in BOM town.

Variant structure, configurable bill of material, modular BOM… the industry invented multiple names to cope with the complexity of communication and product development processes in manufacturing organizations. The core idea of modularization or configuration is not directly related to assembly to order process (ATO), but used widely for configurable and complex products. You can see 150% BOM, 200% BOM and similar BOM organization maintained by engineering department to facilitate creation of final products from predefined parts and sub-assemblies. The product development is actually divided into two essential steps – create your modular (150% BOM) and create a planning bill of a specific product. The last one will allow you to roll out cost and delivery time.

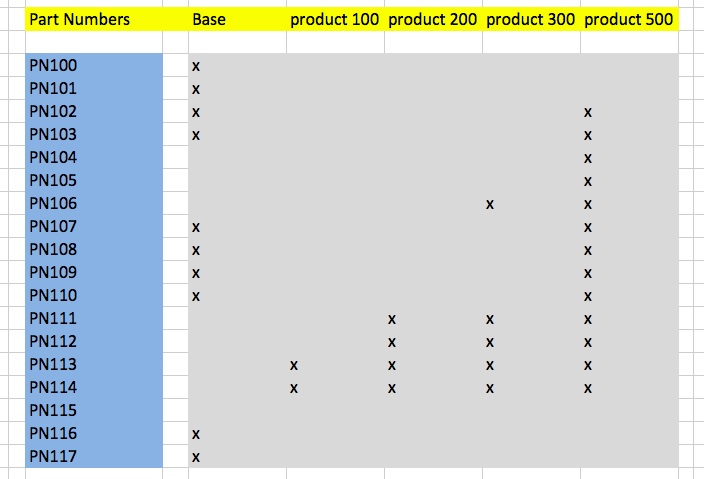

So, why engineers created 150% BOM concept? Do we really need that? In my view, the approach was a way for engineers to manage the complexity of product structure and product variation. You can see it for product configurations and also in bill to order (BTO) situations where complex product development is managed in a way of product technological foundation combined with features developed for specific customer. With absence of better tools, Excel spreadsheet becomes the best product configuration environment and matrix with 150% BOM is the simplest model to present that.

Ed’s blog made me think about future of “150% BOM” and matrix BOM organization. In my view, the concept will disappear in the future. In my view, the complexity of product environment is growing. In many situation, to produce 150% BOM is not feasible anymore. With the level of product complexity, mix of mechanical, electronic and software components, ability of engineers to bring them all together into one 150% BOM can be not practical and even less efficient. We will need to invent new tools to manage the complexity of configurations and product data. With growing demand for personalization, we are not far from the situation, PLM and ERP systems will have to roll out bill of materials individually configured for a specific customer (and this is not only in aerospace and defense industry).

What is my conclusion? Growing complexity of products, move to mass customization, regulatory and cost pressure, global manufacturing – this is a reality of modern manufacturing environments. We need to develop a new approach how to manage product development and manufacturing of these products. Product configurations and BOM is a centerpiece of this approach. A simple 150% BOM spreadsheet will be replaced with new BOM tools. Just my thoughts…

Best, Oleg

The post Why 150% BOM will be obsolete in the future? appeared first on Beyond PLM (Product Lifecycle Management) Blog.